Vanishing Windmills

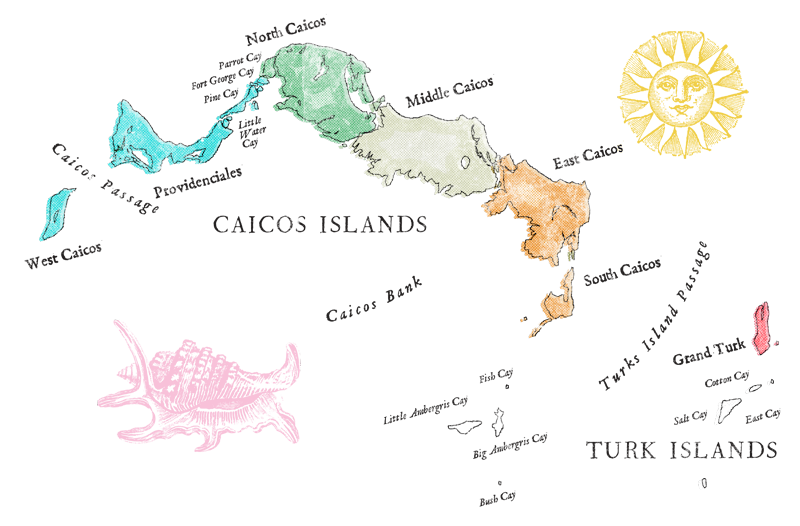

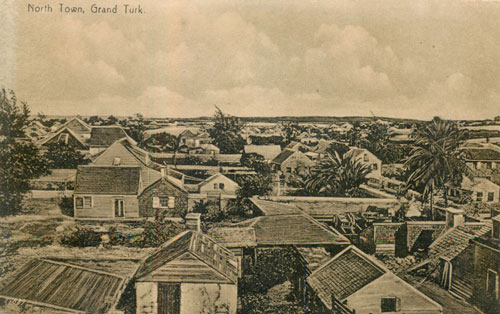

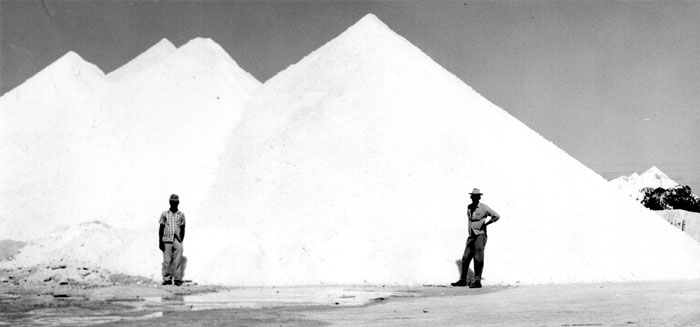

Ruined windmills dot the landscape of Salt Cay, South Caicos, and Grand Turk.

Not so long ago, they helped the flow of brine and pickle between the salinas — salt ponds — that cover these islands. They are the lasting legacy of the Islands’ sea salt industry. Invariably, first time visitors comment on them. Like lighthouses, windmills cast a spell, reminders of a life that was, a life now gone.

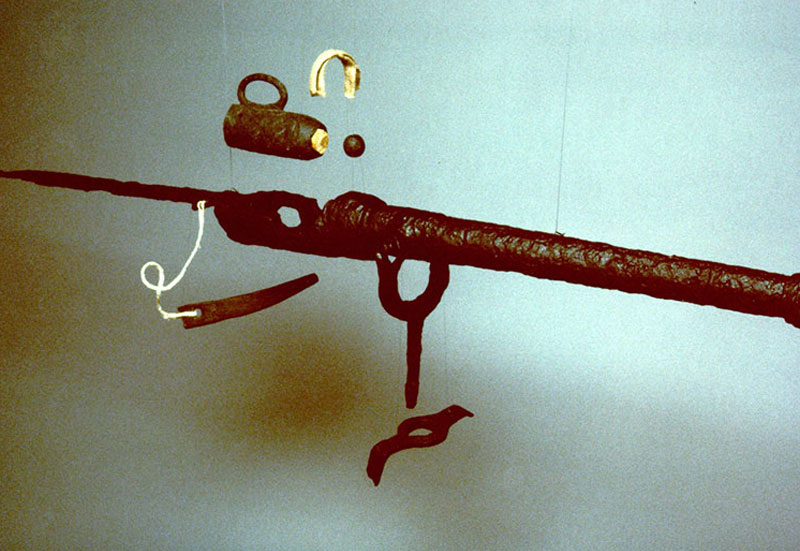

In December 1997, the Museum took a step towards recreating a full-scale working windmill. A small group recovered a critical windmill component — the cast-iron millhead with transmission gears and mill-vane hub. The millhead, weighing close to 200 pounds, performed a critical function. Turning on huge ball bearings, it allowed the tail of the mill to respond to changes in wind direction and pivot the head of the mill to keep the sails on the vanes properly trimmed to the wind. Big pinion gears transmitted the rotation of the mill’s vanes from a horizontal to a vertical shaft, sending the motion down the tower to where its axis was changed back to horizontal as it engaged the paddle wheel. At the end of the mill shaft, the big wooden mill vanes with their canvas sails radiated out of a big hub with four angled sockets. The hub and the millhead are a critical part of any windmill, and new ones, as far as can be determined, are no longer available.

In December 1997, the Museum took a step towards recreating a full-scale working windmill. A small group recovered a critical windmill component — the cast-iron millhead with transmission gears and mill-vane hub. The millhead, weighing close to 200 pounds, performed a critical function. Turning on huge ball bearings, it allowed the tail of the mill to respond to changes in wind direction and pivot the head of the mill to keep the sails on the vanes properly trimmed to the wind. Big pinion gears transmitted the rotation of the mill’s vanes from a horizontal to a vertical shaft, sending the motion down the tower to where its axis was changed back to horizontal as it engaged the paddle wheel. At the end of the mill shaft, the big wooden mill vanes with their canvas sails radiated out of a big hub with four angled sockets. The hub and the millhead are a critical part of any windmill, and new ones, as far as can be determined, are no longer available.

Long the main source of income, the salt industry is one of the “big stories” in Islands’ history. A reconstructed windmill would stand as a memorial to those who worked for centuries under the brutal conditions prevailing in the salt trade. It would be a “super artifact,” one that is not only large but provokes an emotional response from visitors. As a working exhibit and kinetic sculpture, it would draw visitors as any “super artifact” does.

In the summer of 1996, the Museum compiled an informal inventory of the windmills. With the help of volunteers, we measured a mill in Hawk’s Nest Salina and another in Town Salina, then another — a rare survivor of the old carousel-type windmill, whose vanes rotated, as the name implies, like a merry-go-round.

We were on the lookout for a millhead bearing in good enough shape to exhibit and perhaps able to be reconditioned to resume work on top of a reconstructed windmill. We visited Great Salina and Hawk’s Nest to record mill sites and scout for usable millheads among the ruins of collapsed mills. Those we found were inevitably heavily corroded. Worse, they were inaccessible: It was a daunting prospect to consider cutting one free in the middle of a salina, and then carrying the heavy casting a long distance with treacherous footing to where it could be loaded on a truck.

We were on the lookout for a millhead bearing in good enough shape to exhibit and perhaps able to be reconditioned to resume work on top of a reconstructed windmill. We visited Great Salina and Hawk’s Nest to record mill sites and scout for usable millheads among the ruins of collapsed mills. Those we found were inevitably heavily corroded. Worse, they were inaccessible: It was a daunting prospect to consider cutting one free in the middle of a salina, and then carrying the heavy casting a long distance with treacherous footing to where it could be loaded on a truck.

One possibility remained …. a windmill standing on the edge of the North Salina, opposite the Guanahani Hotel. What we saw was not encouraging. Only the base of the mill was still standing. Then we saw the millhead lying in the salina. Amazingly, it was in good shape. Evidently, one of the 1996 hurricanes had toppled it, and corrosion was not advanced.

Turks & Caicos Utilities graciously provided a bucket truck and crew the next day. Once Dressel kept his promise to be the one to go into the muck and trash of the salina to fasten the cable, it took the TCU crew but a few minutes work to heave the bearing out. In a few minutes more, Dressel and Sherlin Williams had freed it of the rotten wooden mill tower and shaft.

TCU transported the millhead to the Museum’s lab, where it was off-loaded and washed. Sherlin Williams and Museum Chair Grethe Seim immediately set to work with scaling hammers, cleaning on the muck and corrosion. Meanwhile in the exhibit shop upstairs, Juan Rodriguez used the measured drawings to painstakingly build a model windmill in cedar.

While acquiring the millhead removed a big obstacle to recreating a windmill, the work is really only beginning. The millhead, if used in a replica mill, will require complete rebuilding in a machine shop. By some miracle the millheads may still in production or old stock parts may be available. We will only know if we can locate the original manufacturer. If all other avenues yield no results, it may even be necessary to use the recovered millhead to produce a mold and actually recast an entirely new one.

While the mill measured in Town Pond answered many questions, the parts that were missing posed others: Exactly how were the vanes and tail construced? How were the sails made and attached? Salt production on Grand Turk ceased nearly two generations ago, and the construction, maintenance, and opertaion of windmills ceased to be a concern for very many people a good while before that.

The millheads were custom-made to fit this particular mill design, so the plan for the mill as a whole either originated with the millhead manufacturer or plans were furnished to the foundry so that it could be designed to fit. Solving the mystery of the origin of the millhead is essential.

Once the mystery is solved, we will be well on the way to creating a replica of a salina windmill. What better memorial to those centuries of labor than a working exhibit of an object synonymous with salt-making?

Once the mystery is solved, we will be well on the way to creating a replica of a salina windmill. What better memorial to those centuries of labor than a working exhibit of an object synonymous with salt-making?